Faced with the foam that is constantly generated in the wastewater pool, do you often face this problem? But there is no countermeasure~

We provide products that defoam quickly and can achieve long-lasting defoaming capabilities with a very small amount ~

What impact does the foam at the outlet have on water quality? This is a question that many people have in mind! In fact, during actual visits to various wastewater plants in the north, central and south, we found that foam at the discharge outlet does not necessarily have an impact on water quality, but it does cause an obvious and annoying negative outlook on the discharge water. Therefore, most users use defoaming agents for drain water. The main purpose is to eliminate external doubts about the drain water.

▲In wastewater treatment plants, it is common to see long stretches of foam on the pool or blown into the air by the wind

In addition to foaming in the discharged water, disturbances at high and low levels between the wastewater pools form a large amount of foam, which is mainly caused by the presence of surfactants in the water. , this foam can be classified as physical and chemical foam. If not handled properly, it will affect the efficiency of the entire wastewater treatment and cause the problem of sludge floating. Another cause of foam is the biological foam produced by the biological pool. This foam is mainly caused by actinomycetes in the biological pool. Due to the high viscosity of the bacteria, it is easy to adhere to the tiny aeration bubbles in the pool, and then float to the surface of the pool with the bubbles, gradually accumulating into a large-scale foam. The following is a test of high-quality and highly stable non-silicone defoaming agents for these two foams to provide a reference solution for wastewater treatment plants encountering the same problem.

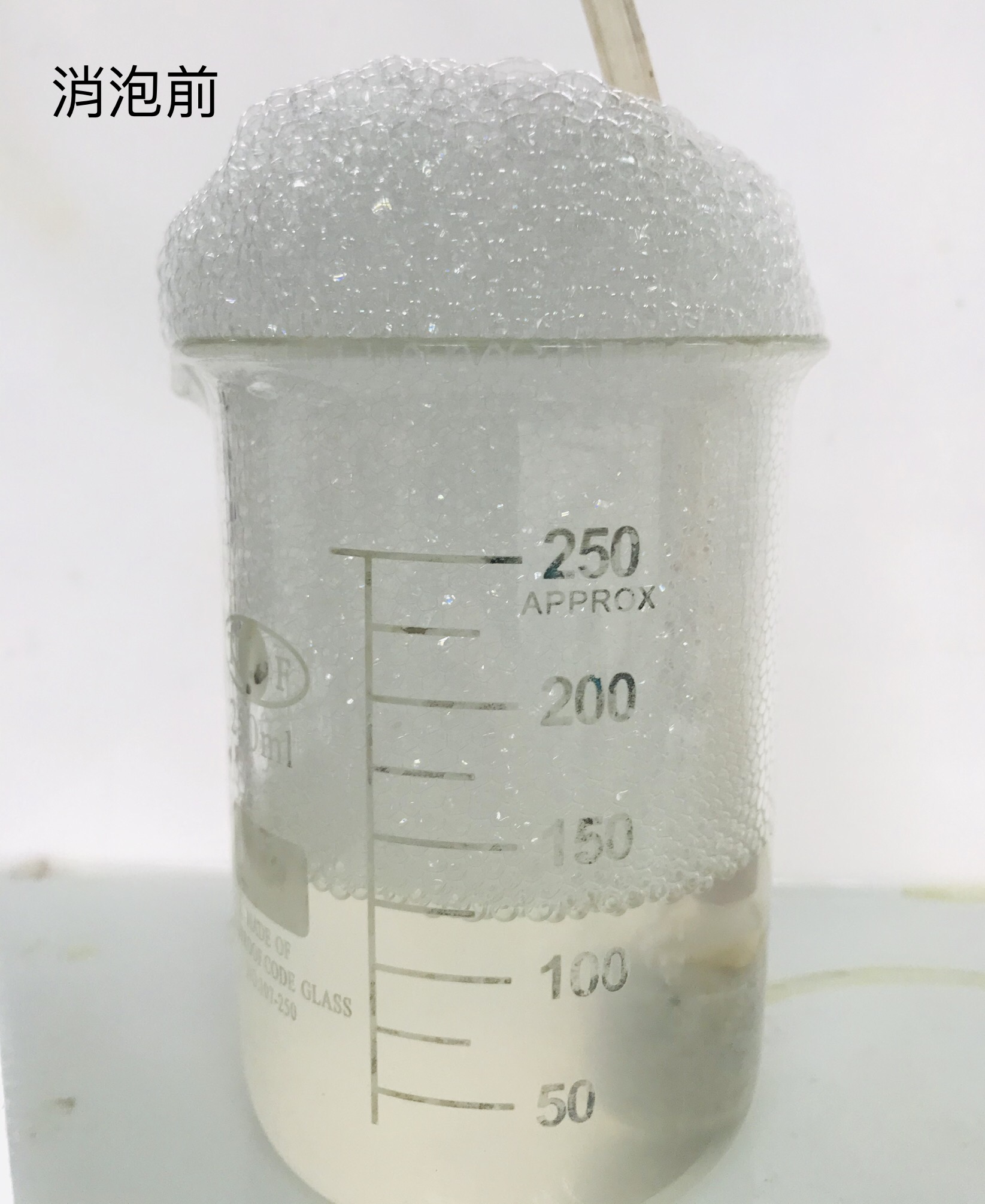

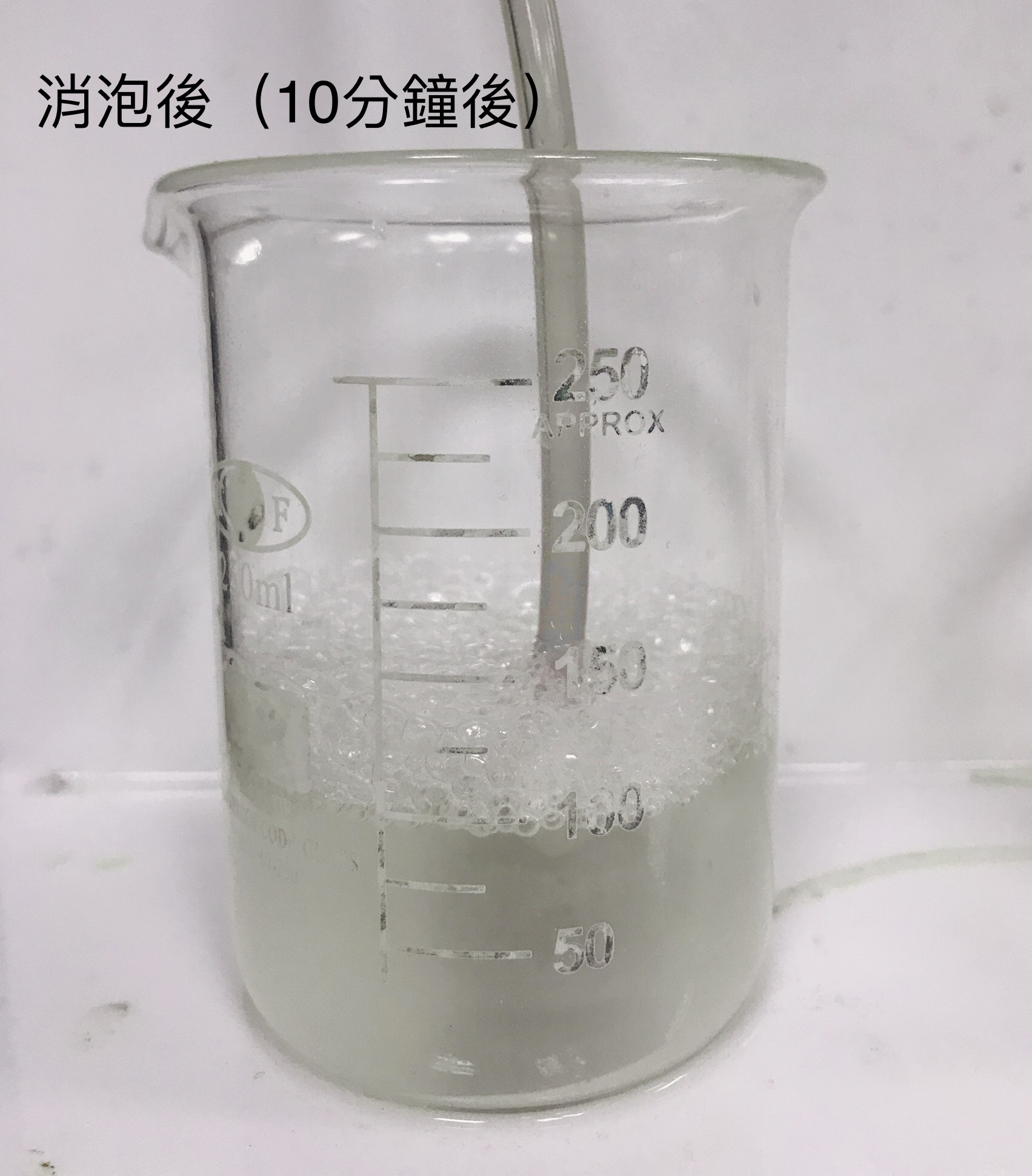

Actual measurement 1: Process cleaning wastewater

Wastewater type: process-end cleaning wastewater

Wastewater volume: 12 tons/day

In this process, the water-based cleaning agent is configured in the degreasing tank at a concentration of 5%. The water washing tank in the later stage will be discharged to the wastewater field due to the high water pollution concentration. Therefore, Wastewater plants must face and treat wastewater containing surfactants every day. The surfactant in the water will be disturbed by the water, causing a large amount of foam to overflow from the tank. By adding high-quality and stable non-silicon defoamer, foam can be eliminated instantly and lasts for a long time.

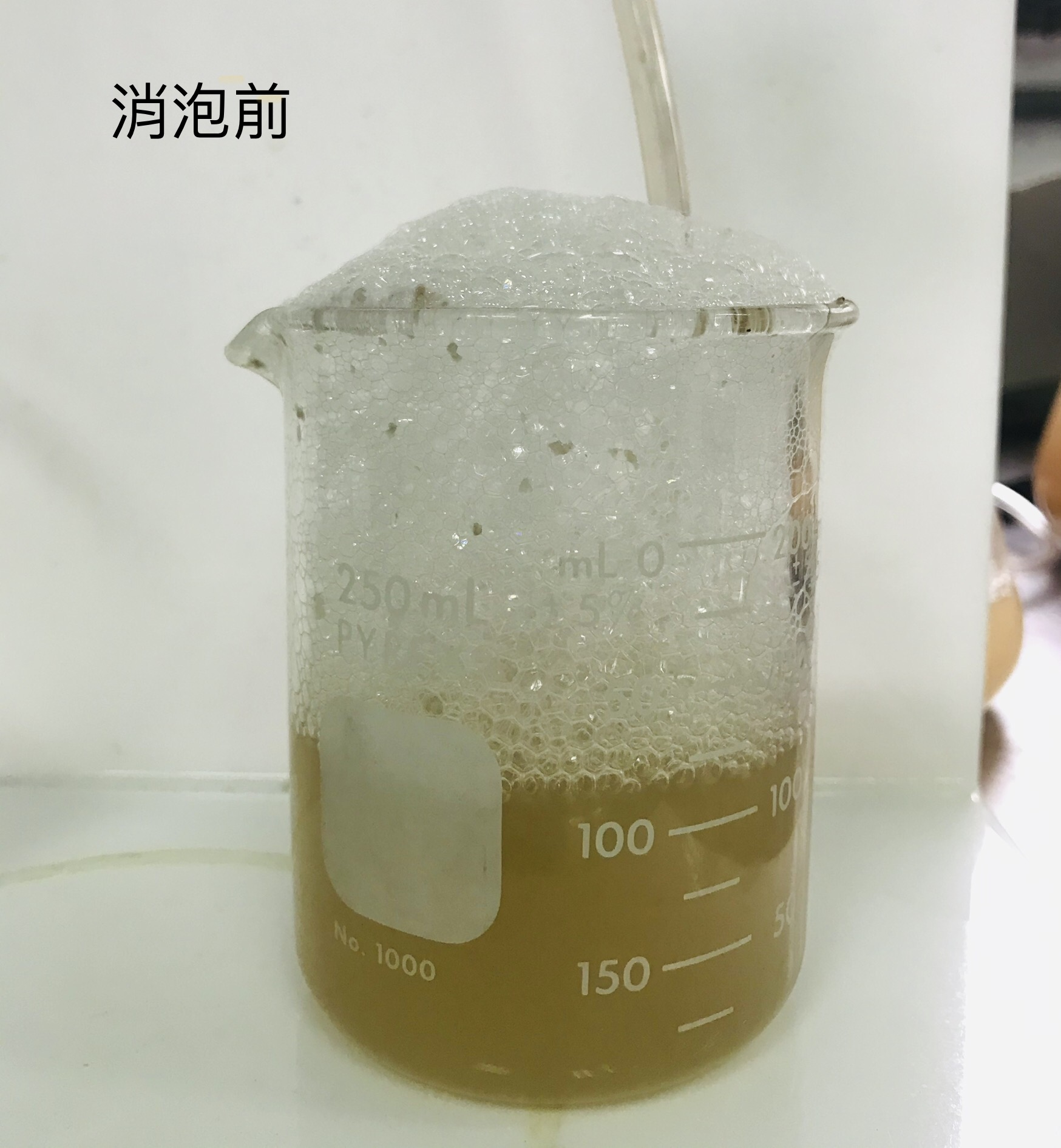

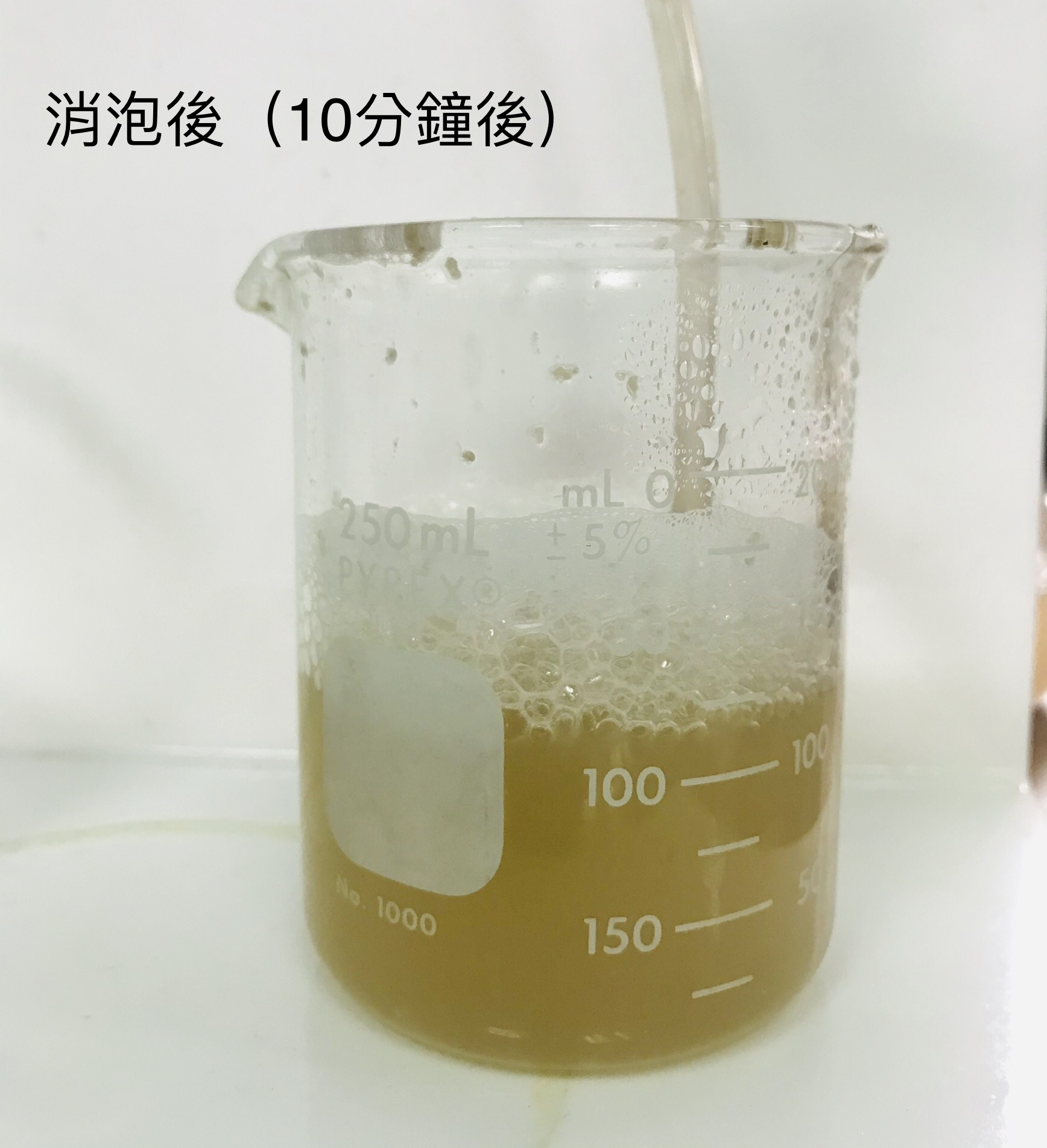

Actual measurement 2: Activated sludge tank wastewater

Wastewater type: chemical industry activated sludge tank

Wastewater volume: 300 tons/day

This activated sludge tank is discharged from time to time with high organic matter wastewater from the process end, causing the activated sludge tank to often produce biological foam overflowing the tank surface. By adding highly efficient and non-hazardous non-silicon defoaming agents, in addition to effectively suppressing foam generation, the concern about the harmful effects of defoaming agents on microorganisms can be eliminated.

Please refer to the following link for product introduction videos: