Vibration Grinding Wastewater Treatment Innovation! Achieving Sludge Reduction Simultaneously~!! Functional Coagulant Application PART I

Wastewater treatment no longer relies on lime, significantly reducing concerns about fluctuating sludge disposal costs~

Vibration grinding is a process that smoothens the surface of workpieces by using abrasives, processing fluids, and grinding agents in a vibrating machine, which frictionally interacts with each other to remove the original rough surface irregularities. The wastewater from vibration grinding mainly contains a large amount of surfactants of polishing compounds, oil, and polishing agents adhered to metal processing products. However, while various chemicals initially aid in the surface smoothness of workpieces, they later pose challenges in wastewater treatment such as difficulty in flocculation and high COD levels.

▲ Conventional vibration grinding wastewater often uses inexpensive lime as the main treatment solution, resulting in significant sludge generation and subsequent disposal challenges.

Kelly Chemicals has introduced economically viable composite coagulation technology from Europe and the United States. After understanding the composition of vibration grinding wastewater (including grinding materials, rust inhibitors, polishing fluids, and other additives), we proposed corresponding and convenient treatment methods, effectively solving the challenges of high oil content and difficult flocculation. Below are two practical cases:

A hand tool manufacturing plant in Taichung replaced a large amount of lime with functional coagulants for grinding wastewater treatment.

The vibratory grinding wastewater generated approximately 15 tons per day. Lime was used to treat this wastewater at a rate of about 100 kilograms per day, resulting in a substantial amount of sludge generated from lime and facing increasing sludge disposal costs and decreasing disposal channels. By using a functional coagulant treatment solution, the grinding fluid and additives added to the vibration grinding process can be effectively treated with a relatively small amount of coagulant, enabling effective solid-liquid separation. A comparison of the two solutions is shown in the table below:

| Lime Treatment Solution | Functional Coagulant Treatment Solution | |

| Dosage | 33 KG/ton | 5 KG/ton |

| Sludge Volume | Approximately 18 tons/month | Approximately 8 tons/month |

| Operating Method | Powder addition, manual loading | Liquid addition, quantitative pump control |

| Chemical Storage | Occupiesa large space, approximately 18 pallets/month | Occupies a small space, approximately 2 pallets/month |

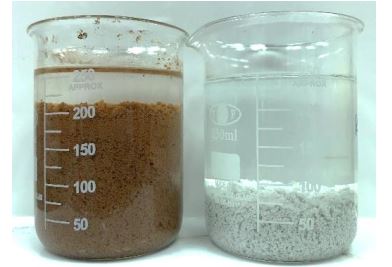

▲ The actual treatment results are shown in the image above, with the left cup representing the original solution and the right cup representing the solution treated with the functional coagulant.

A metal processing plant in Taichung replaced ferric chloride with a functional coagulant.

The processing plant mainly undertakes metal processing operations such as vibration grinding, sandblasting, and polishing. The vibration grinding generates approximately 8 tons of wastewater per day. The original treatment method involved adding a large amount of ferric chloride to coagulate impurities and grinding additives, resulting in a significant amount of iron-based sludge and heavy monthly disposal costs. The functional coagulant can effectively treat the components in the grinding wastewater without adding excessive and inefficient coagulants, leading to reduced sludge generation. The comparison table is as follows:

| Ferric Chloride Treatment Solution | Functional Coagulant Treatment Solution | |

| Dosage | 40 KG/ton | 5 KG/ton |

| Sludge Volume | Approximately 13 tons/month | Approximately 6 tons/month |

| Operating Method | Quantitative addition, water color avoidance | Quantitative addition, transparent water color |

| Chemical Storage | High demand, frequent tanker requests | Minimal demand, approximately 1 pallet/month |

▲ The image above shows the actual treatment of wastewater, with the left cup representing the ferric chloride treatment solution and the right cup representing the sludge and clarified liquid produced by the functional coagulant treatment solution.