E-Weld Shield

Surface Protection for Plasma and Laser Cutting Machines - Coating the workpiece rods to prevent the accumulation of a large amount of slag in the cutting by-products. Using E-WELD Shield enables faster cleaning of steel bars and allows for longer use. This helps streamline and save time and cost in the workflow. Through a spray system, E-WELD Shield is applied in the best way to achieve effective protection.

- Preventing the accumulation of a large amount of slag on the rods during plasma and laser cutting.

- Saving time: Slag is easy to remove.

- Improving cutting results: The incisions from plasma and laser cutting machines lie flat on the cutting table.

- Exclusion. Spray system (provided in the E-WELD Shield kit)

Product description:

E-WELD Shield is used in the plasma and laser cutting field. It is easy to apply through a spray system and provides optimal surface protection. Coating the workpiece rods with E-WELD Shield prevents the accumulation of a large amount of slag by incorporating ceramic additives in the product. Additionally, this type of slag is easier to clean, reducing the time needed for rod maintenance and extending the system's uptime. Moreover, cost savings are achieved as there is no frequent need for metal strip replacements. Placing the workpieces flat on the rods improves the quality of the cutting results.

- Cleaning speed and longer rod usage time.

- The inclusion of ceramic additives prevents slag accumulation.

- Economically: 1 kilogram of E-WELD Shield is typically sufficient for approximately 100 kilograms of demand or 20 square meters.

- CLP regulations do not require labeling.

Application areas:

Jianshan protection for laser/plasma cutting

Advantage:

Improve machine productivity

Increase capacity utilization

Reduce maintenance work time

Laser/Plasma Cutting Cost Optimization

How to use:

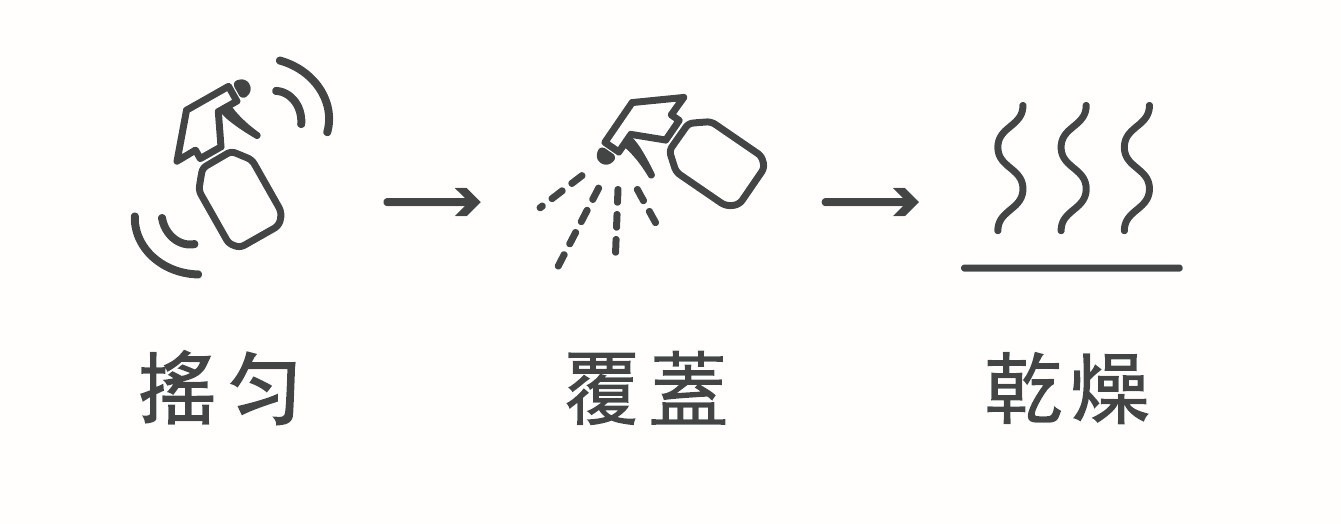

Mixing> Covering>Dry

Before use, thoroughly mix E-WELD Shield, then apply a layer of E-WELD Shield to new or cleaned steel bars, ensuring good coverage. It is advisable to repeat this process. Let it dry for about 1 hour. After approximately 1 hour, remove the slag. After 4 weeks, apply a new layer of E-WELD Shield. 1 kilogram of E-WELD Shield is typically sufficient for approximately 20 square meters.

In the area where E-WELD Shield is applied, there is no splatter attached.

Video Introduction