Fast-Drying Solvent Substitute, Cyclohexane-Free, Compliant with EU and International Leading Standards

Not only suitable for pre-painting cleaning, but also applicable for pre-adhesion, residue removal, and pre-shipment cleaning of plastic injection parts!!

Features of FT

The FT series is water-based and serves as an effective substitute for traditional solvents, cellulose thinners, and cold cleaning agents. They are non-flammable and dry much faster on surfaces compared to other water-based products. FT 300 cleans without the need for surfactants, making it particularly suitable for smooth and glossy surfaces such as glass and metal. FT 200 and phosphate-free, providing temporary corrosion protection for cleaned surfaces.

Not containing harmful substances means not only simplified storage but also transportation, thereby reducing costs: using water-based FT cleaners as solvent substitutes can save disposal and storage costs, as well as training, insurance, and transportation costs. Additionally, if applied properly, cleaner consumption can be reduced by up to 50% compared to traditional solvents.

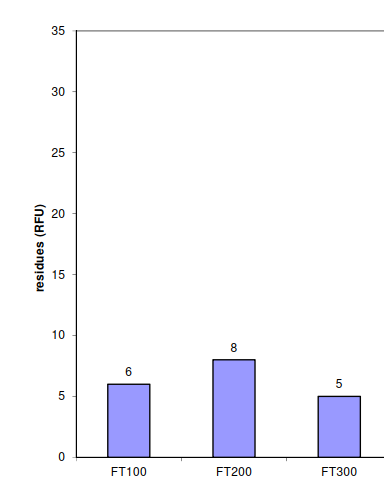

The low residue formula of FT ensures tighter adhesion and coating!

▲ Results of residual testing on aluminum plates sprayed with three types of FT fast-drying cleaners show very low residue levels.

Applications

FT cleaners are primarily used for surface pretreatment, suitable for removing adhesive residues or contaminants caused by processing oils. Among other applications, they are used for cleaning and degreasing before coating, bonding, labeling, or painting. They can remove residues that adversely affect the adhesion of surface materials. In final cleaning, fingerprints, dust, and light oils are effectively removed.

In addition, FT fast-drying cleaners can be applied in four industrial areas:

1.Cleaning before bonding

Many industrial fields require bonding of various materials, requiring surface cleaning to ensure no residues that may affect the strength and durability of the bond. Some manufacturers may also need to apply labels or safety instructions on equipment surfaces, which also require thorough surface cleaning to prevent labels from peeling off. FT series products can be used in such cases.

2.Removal of glue

On some workpieces, residues of glue may remain on the surface after previous adhesion. When these adhesives have not completely cured, some people may use alcohol or stain removers. However, alcohol poses certain risks and may not be very effective, while stain removers contain toxic and carcinogenic substances. In such cases, using the non-toxic, low VOC FT series is an excellent choice.

3.Product finishing

In some industries such as furniture, exhibition or store structures, machinery manufacturing, and plastic injection factories, products require surface polishing and smooth finishes. In these cases, our FT series is an excellent choice.

4.Cutting and drilling of aluminum

During the cutting of aluminum, industrial alcohol is commonly used as a lubricant due to cleaning issues with industrial lubricants. In this case, using FT 200 is an excellent lubricant and can replace alcohol, reducing the occurrence of accidents related to workplace safety.

Product Comparison

| FT200 | FT300 | UNO SF | Prolaq L400 | Nikutex 5300 | CL 6500 | Degreasing Oil | |

| Product Series | Fast-Drying | Fast-Drying | Water-Based | Solvent-Based | Solvent-Based | Solvent-Based | - |

| Degreasing Power | + | + | + | + | + | + | + |

| Drying Speed | + | ++ | - | - | - | - | +++ |

| Adhesive Removal | + | + | - | + | + | + | + |

| Pencil Stain | + | + | + | + | + | + | + |

| Marker Stain | - | - | - | + | + | + | + |

| NSF Certification | v | - | v | - | - | - | - |

| Hazard Level | General | General | General | General | General | General |

3 Hazardous Categories, Contains Cyclohexane |

| Real Cases | Removal of excess glue after bonding plywood | Removal of roller-sealing residue in printing equipment | Cleaning of large machinery and floor | Cleaning ink in label printing factory | Cleaning water-based paint pipelines in painting plant | Cleaning barrel tanks in pen manufacturing factory | - |

Video Introduction