Alternative to Traditional Acid Pickling Agents - Neutral DECORRDAL® 20-1

Effectively pre-treats the surface of laser-cut edges, preventing flash rust, while being neutral, thus not subject to hazardous materials management requirements.

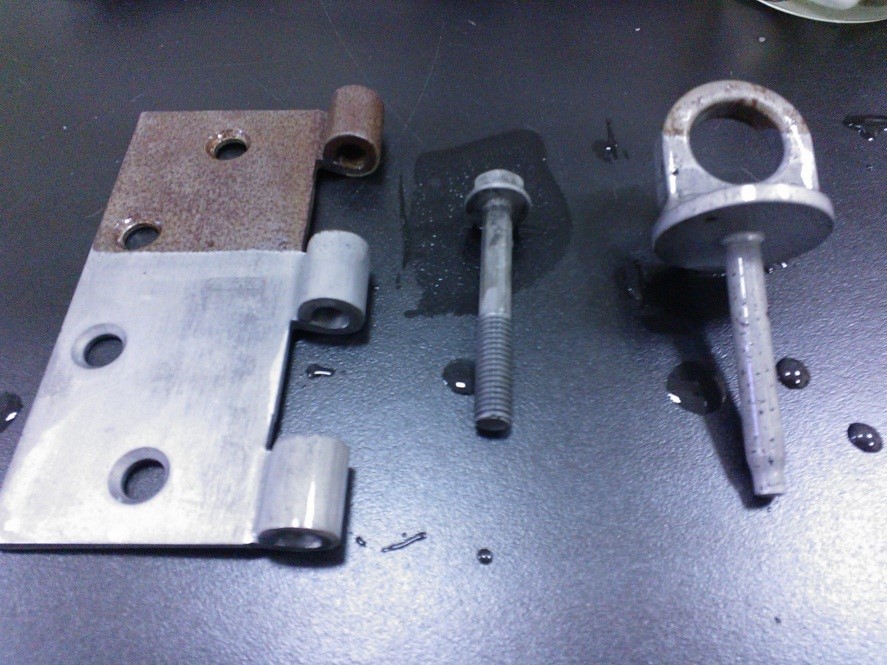

▲ The lower half shows the result after soaking in 10% Decorrdal 20-1, with gentle ingredients that do not harm the substrate.

Mechanism of Action

As a so-called neutral acid pickling agent, DECORRDAL® 20-1 has a pH value between 6.5 and 7.0, which remains in the working solution and is almost independent of the concentration of the pickling solution. Due to its special composition, DECORRDAL® 20-1 prevents the formation of phosphate layers and helps to eliminate flash rust, which may occur particularly in downstream rinsing stages. Additionally, no sludge formation due to dissolved iron (iron phosphate) was observed when using DECORRDAL®.

Applications

1.Pre-treatment of Laser-cut Edges

DECORRDAL® provides optimized preparation of laser-cut edge surfaces for subsequent coating processes, ensuring maximum coating adhesion.

2.Preparation of Steel Surfaces and Aluminum

DECORRDAL® 20-1 is suitable not only for acid pickling but also for treating galvanized steel surfaces and aluminum materials. During the preparation process, this surface is roughened but not pickled. This function does not include the immersion of aluminum and zinc in the pickling solution. A positive side effect: the service life of the medium is not reduced due to contamination.

- Excellent rust and scale removal for ferrous and non-ferrous metals

- Very effective for removing oxide layers after thermal processing or laser cutting

- Effective from bath temperatures as low as 30°C

- No hazardous labels

Operating Procedure

Application: In spraying or immersion processes with added surfactants

Optimal temperature range: 30 to 45°C

Concentration: 3% to 5% for spraying processes / 5% to 15% for immersion processes

Treatment time: Depends on the thickness of the oxide layer

Process control: Conductivity (neutral pH value)