Traditional fillers unable to solve? Let hollow glass microspheres assist you~

Kelly Chemical offers various specifications of hollow glass microspheres, effectively enhancing the added value of your products

Common fillers such as silica, calcium carbonate, ceramic powder, and titanium dioxide, although capable of replacing some resin materials to reduce costs, are accompanied by numerous drawbacks that fail to elevate the product. Let's explore why hollow glass microspheres would be the optimal choice for fillers from several perspectives!

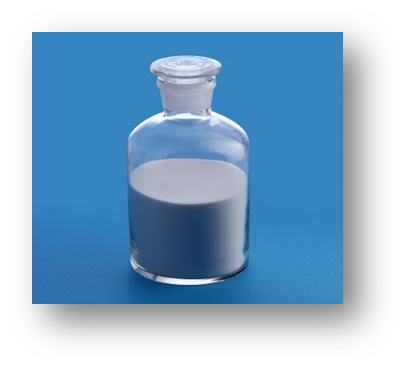

▲ Hollow glass microspheres (as shown above), white flowable powder, appear as transparent hollow spheres under a microscope.

Hollow glass microspheres are a forward-looking new material with micro-level smooth surfaces, primarily composed of borosilicate glass. They exhibit various properties such as low density, high strength, high temperature resistance, acid and alkali resistance, low thermal conductivity, electrical insulation, good flowability, chemical stability, and dimensional stability.

1.Extremely low density, the best choice for cost-saving and lightweight carbon reduction materials.

Traditional fillers generally have a density of >2.5 g/cm³, while hollow glass microspheres have a density of only 0.2-0.6 g/cm³. In terms of the volume/price ratio, hollow glass microspheres are more cost-effective due to the significantly larger volume they can fill compared to traditional fillers, even though they may have a higher unit weight price. Moreover, the weight occupied by hollow glass microspheres in the same volume is only 1/5 or less than that of traditional fillers. For industries such as aerospace, automotive, rubber, and footwear, lightweighting is crucial, as it reduces fuel usage and subsequently lowers CO2 emissions, making hollow glass microspheres the optimal choice for lightweight carbon reduction materials.

|

Product Types |

Density(g/c.c) |

|

Calcium Carbonate |

2.7 |

|

Talcum Powder |

2.7 |

|

Silica |

2.7 |

|

Barium Sulfate |

4.3 |

|

Hollow Glass Microspheres |

0.2-0.6 |

2.Extremely low thermal conductivity and high chemical stability, the best choice for thermal insulation and corrosion-resistant materials.

The thermal conductivity of hollow glass microspheres is only 0.038-0.060 W/m·K, making them widely used in thermal insulation coatings. Due to their high chemical stability, they exhibit synergistic effects when mixed with corrosion inhibitors such as zinc oxide. Moreover, they do not significantly increase the viscosity of formulations, which reduces the use of organic solvents and lowers the VOC emissions of products, making them the best choice for thermal insulation and corrosion-resistant materials.

3.Spherical flowability and low expansion coefficient, the best choice for solving fiberglass exposure, finished product warping, and dimensional stability.

Traditional fillers often suffer from problems such as uneven particle size, shape, or temperature-induced dimensional changes. Hollow glass microspheres, due to their spherical shape and smooth surface, have the smallest surface area and low expansion coefficient, allowing them to maintain dimensional stability even at high temperatures. This is crucial for composite materials or finished products made from copper-clad laminate substrates. The rapid cooling properties of hollow glass microspheres are highly beneficial for process speed optimization, making them the best choice for solving issues like fiberglass exposure, finished product warping, and dimensional stability.

4.Low dielectric constant and loss, the best choice for 5G applications.

With the advent of the 5G era, the demand for materials with excellent dielectric properties is increasing. Hollow glass microspheres have extremely low dielectric constant values (approximately 1.6 @10 GHz) and extremely low dielectric loss values (approximately 0.005 @10 GHz), unmatched by traditional fillers. They can be added to high-frequency high-ductility copper-clad laminate substrates, antenna covers, mobile phone cases, server casings, transmission lines, and more. They are the best choice for 5G applications.

In summary, hollow glass microspheres can indeed bring more added value to products than traditional fillers. However, due to differences in applications and processes, there are different requirements for microsphere specifications. It is also possible that you have potential applications that we have not yet considered. Therefore, please do not hesitate to contact us for further discussion~ Thank you.