Do you know that there is a significant difference in the products of hollow glass spheres produced by different processes!!

Kelly Chemical provides hollow glass spheres in various specifications, effectively enhancing the added value of products. Feel free to contact us for further discussion.

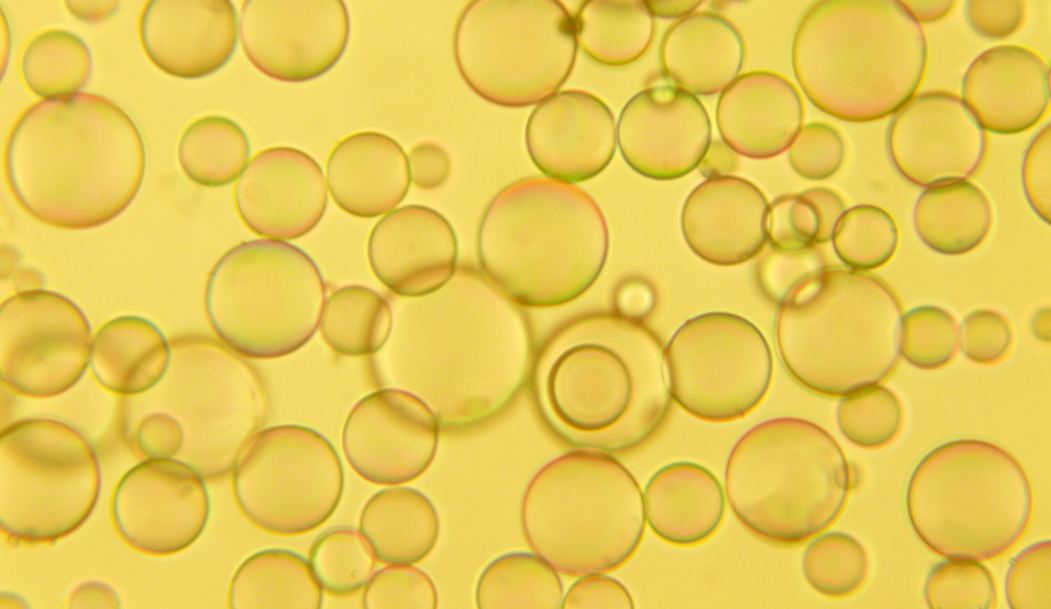

Glass, as we commonly know it, generally refers to silicate glass. Silicate glass, due to its excellent performance, is widely used in various glass products in industrial and civil fields, making it one of the most commonly used materials in our daily lives. Hollow glass spheres are micron-sized hollow thin-walled spherical particles made of silicate glass, containing a small amount of boron oxide, also known as borosilicate glass. They appear as white flowing powder.

Formation and Influencing Factors of Glass

The preparation of glass typically involves mixing raw materials such as silica dioxide, sodium carbonate, calcium carbonate, and borates, followed by high-temperature heating to melt the mixture, then cooling to obtain the glass. This process is called glass melting. Glass melting is a complex physical and chemical change process that can be divided into five stages: silicate formation, glass formation, glass liquid clarification, homogenization, and cooling.

1.Silicate Formation: At temperatures of 800-900°C, sodium carbonate and calcium carbonate decompose into sodium oxide and calcium oxide upon high-temperature heating, which then react with silica dioxide to form sodium silicate and calcium silicate, forming an opaque sintered material composed of sodium silicate, calcium silicate, and silica dioxide.

2.Glass Formation: When the temperature reaches around 1350°C, silica dioxide particles dissolve and diffuse in the molten silicate to form glass.

3.Glass Liquid Clarification, Homogenization, and Cooling: After glass formation, gases in the glass need to be removed, and the components in the glass liquid, especially silica dioxide, need to diffuse to form a homogeneous glass liquid. Only after cooling can a glass with uniformly distributed oxide molecules be obtained. These processes are collectively known as glass liquid clarification, homogenization, and cooling.

Glass formation typically requires high-temperature melting, clarification, and homogenization above 1300°C, which lasts for several hours. Temperatures below 1300°C and times less than 30 minutes make it difficult to achieve glass formation.

Glass melting is one of the most important processes in glass production and a focus of glass industry research. Poor control of glass melting can result in various glass defects, affecting glass quality. For example, if the temperature is too low or the time is too short, silica dioxide may not melt and diffuse, resulting in "stones" in the glass. If the glass liquid clarification and homogenization time is insufficient, gases in the glass are difficult to remove completely, and inorganic salt raw materials such as sodium carbonate and calcium carbonate are likely to remain in the glass. These glass defects significantly affect the mechanical properties and chemical stability of the glass.

Production Processes of Hollow Glass Spheres

Research on hollow glass spheres began in the 1950s and 1960s, driven by the development of the aerospace industry's demand for high-performance materials. After more than half a century of technological development, there are mainly two industrial-scale production processes for hollow glass spheres: liquid drying method and solid melting method.

1.Liquid Drying Method

The liquid drying method, also known as the liquid phase method, spray granulation method, or spray drying method, is based on a sodium silicate solution (commonly known as liquid "water glass") as the base material. Additives such as silica dioxide (commercially known as white carbon black), sodium carbonate, calcium carbonate, and sodium borate are mixed and prepared into a slurry, dehydrated into a powder mixture by spray drying, and then hollowed into spheres at around 1100°C. During the sphere formation process, rapid decomposition and silicate reactions occur among the mixture components. The sphere formation effect is affected by factors such as temperature and raw material formulation. Excessive temperature makes it difficult to form hollow spheres. To understand the glass melting process, we know that the melting point of silica dioxide is high, and it diffuses slowly in the melt, making it difficult to form a homogeneous glass liquid in a short time, resulting in the formation of "stones" in the glass. Therefore, the liquid drying method uses sodium silicate solution (water glass) as the base, introducing molecular silica sources to replace part of the silica dioxide, thereby reducing the formation of "stones" in the glass. In the early stages of liquid drying method production technology, due to the low temperature of sphere formation, silica dioxide could not melt, and almost all sodium silicate was used as the silicon source. This resulted in insufficient silica dioxide content in the product, leading to low strength and limited application of the product. Research institutes in our country have conducted long-term research. By introducing some low-melting borosilicate or mineral powders, the defects of "stones" can be reduced, product performance can be improved, and the improved liquid drying method is also known as the soft chemical method. The advantage of the liquid drying method is its fewer production steps, relatively simple production process control, and low production cost.

2.Solid Melting Method

The solid melting method, also known as the solid-phase method or glass powder method, uses silica dioxide (quartz sand) as the raw material, supplemented with sodium carbonate, calcium carbonate, and borates, to melt glass at high temperatures in a furnace, then grind the glass into powder for hollowing into spheres. The solid melting method undergoes a complete process of silicate formation, glass formation, glass liquid clarification, homogenization, and cooling

Comparison of Two Production Processes:

|

Aspect/Process |

Solid Fusion Method |

Liquid Drying Method |

|

Initial Mixture |

Solid |

Liquid |

|

Process Characteristics |

High-temperature glass melting |

Low-temperature drying solution |

|

Forming Temperature |

1400℃ |

1100℃ |

|

Basic Raw Materials |

High-purity quartz sand |

Sodium silicate solution |

|

Production Cycle |

Long |

Short |

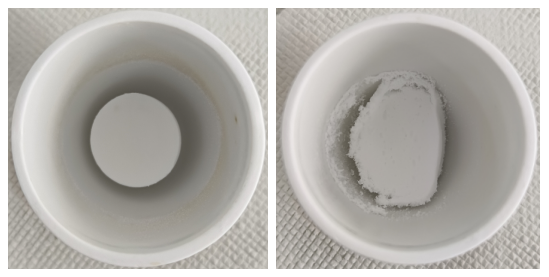

Experimental Heating at 1200°C Inside an Electric Furnace:

(a) (b)

(a) Solid Fusion Method: The hollow glass spheres produced by the solid fusion method, heated at a constant temperature of 1200°C for 30 minutes, softened due to heat, with the uniform glass evenly shrinking in all directions, forming a smooth disc shape inside the crucible.

(b) Liquid Drying Method: The hollow glass spheres produced by the liquid drying method, heated at a constant temperature of 1200°C for 30 minutes, continued to undergo silicate reactions due to heat, resulting in visible depressions and pores formed on the surface due to the gas produced by the reaction.

3.Differences in Products Produced by Different Processes

Comparing the two production processes, the differences in products can be summarized as follows:

Glassification Degree: The solid fusion method undergoes hours of high-temperature glass melting, resulting in complete glassification of the product. In contrast, the liquid drying method, with its lower forming temperature and shorter reaction time, lacks a complete glass formation process, resulting in a lower degree of glassification with only partial glassy components.

Microscopic Structure: The solid fusion method forms a uniform molecular network structure with interlinked oxide molecules in the glass, while the liquid drying method results in a mixture of glassy and silicate sintering materials due to reactions of the raw materials, with un-melted materials embedded in the glassy structure.

Chemical Stability: Products from the solid fusion method, being completely glassified, exhibit high chemical stability as inert materials, with good compatibility with other substances. On the other hand, products from the liquid drying method may contain residual undecomposed inorganic salt raw materials, which can lead to precipitation and decomposition of the product.

Thermal Stability: Products from the solid fusion method are resistant to high temperatures and corrosion, whereas products from the liquid drying method are prone to moisture absorption, clumping, and decomposition at high temperatures.

Strength: Products from the solid fusion method have higher strength compared to those from the liquid drying method.

Table summarizing the differences in products from different processes:

|

Aspect/Product |

Solid Fusion Method Product |

Liquid Drying Method Product |

|

Glassification Degree |

High |

Low |

|

Macroscopic Performance |

Good dispersibility and flowability |

Prone to moisture absorption and clumping |

|

Microscopic Structure |

Molecular network structure |

Contains un-melted materials |

|

Chemical Stability |

High |

Low |

|

Thermal Stability |

High |

Low |

|

Strength |

High |

Low |

Products from the solid fusion method exhibit excellent performance, better compatibility with other materials, precise particle size control, and thus find wider applications, such as:

- In injection molding and extrusion processes with mixing and high shear forces, the breakage rate of hollow glass spheres can be controlled below 7%, and with appropriate processing adjustments, even below 3%, while other products typically have a breakage rate close to 20%.

- Better compatibility and dispersibility with matrix materials result in composites with better homogeneity and higher strength, as well as improved mold filling and demolding performance.

- Materials like coatings and colloids requiring resistance to environmental changes exhibit better aging resistance, ensuring long-term stable performance.

- Solid buoyancy materials exhibit higher strength and lower water absorption rates, suitable for deeper sea operations.

The liquid drying method, with lower production costs, mostly applies to applications where high strength is not required or for producing materials for one-time use, such as mold processing materials.

# Hollow Glass Spheres # Energy Saving and Carbon Reduction # Lightweighting # Hollow Glass Microspheres # Thermal Insulation Fillers # Low Dielectric Constant