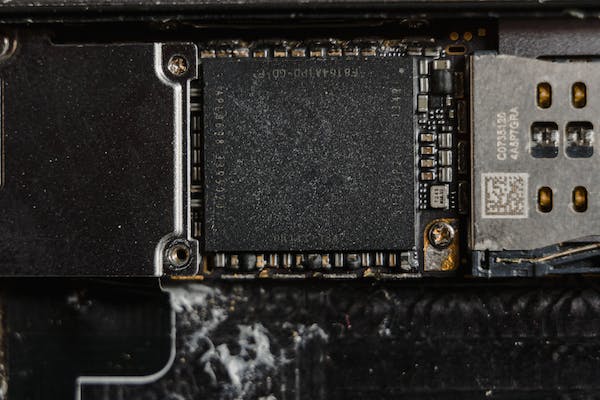

Do you have experiences with fractures caused by thermal stress during thermal expansion and contraction due to differences in the coefficient of thermal expansion between silicon chips and substrates? Lowering the CTE of epoxy resins, with high filler loading of spherical silica, would be your best choice!!

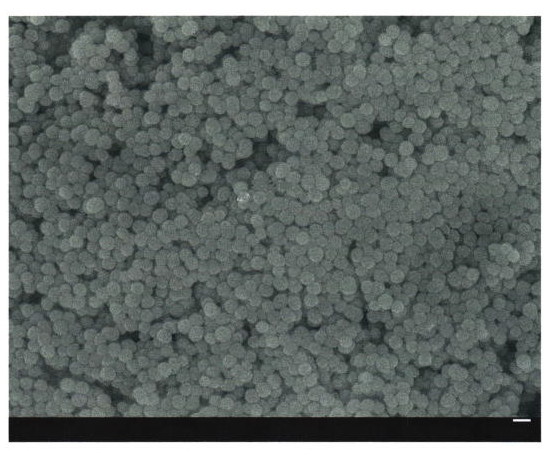

Kelly Chemical offers various high-spec spherical silica materials (nano/micron), which have been proven to achieve high filler loading, enhancing strength and reliability.

Now, let's introduce the main applications of spherical silica·

1.Epoxy Molding Compound (EMC) / Molding Underfill (MUF) - Mainly composed of epoxy resin, phenolic resin, catalyst, and silica micro-powder. Among them, inorganic filler silica (60~90wt%) is the most significant component, determining the product and processing properties.

2.Thermal Interface Material - Whether it's a heat sink or thermal glue, silica micro-powder provides high thermal conductivity, low viscosity, and high flexibility.

3.OLED PI film - Adding silica micro-powder can reduce CTE, improve physical properties, and achieve high transparency without aggregation due to nano-size.

4.3D printing - Silica micro-powder can also provide the finished product with low viscosity, reduced CTE, and improved physical properties.

5.Copper foil substrate - The high filler loading of silica micro-powder can reduce costs, increase thermal conductivity, reduce the coefficient of thermal expansion, and enhance strength. If there are requirements for heat dissipation (alumina powder) and dielectric performance (hollow glass spheres), we also provide corresponding solutions.

Currently, the high-end nanoscale and submicron spherical silica powder market is mainly dominated by Japanese manufacturers such as Adamatechs, Denka, Tatsumori, etc. We provide corresponding products that have been verified by multiple customers. Feel free to request samples for testing.

#SphericalSilica #LowCoefficientofThermalExpansion #HighFillRate #GoodFlowability #ElectronicEncapsulationFiller #LowDielectricConstant #EpoxyMoldingCompound #MoldingUnderfill #ThermalInterfaceMaterial #PIfilm #CCL #3DPrinting